STRÖDTER Handling Technology GmbH

Gabelsbergerstraße 6 • 59069 Hamm Germany

Phone: +492385921210 • Fax: -9212121

To the inquiry form

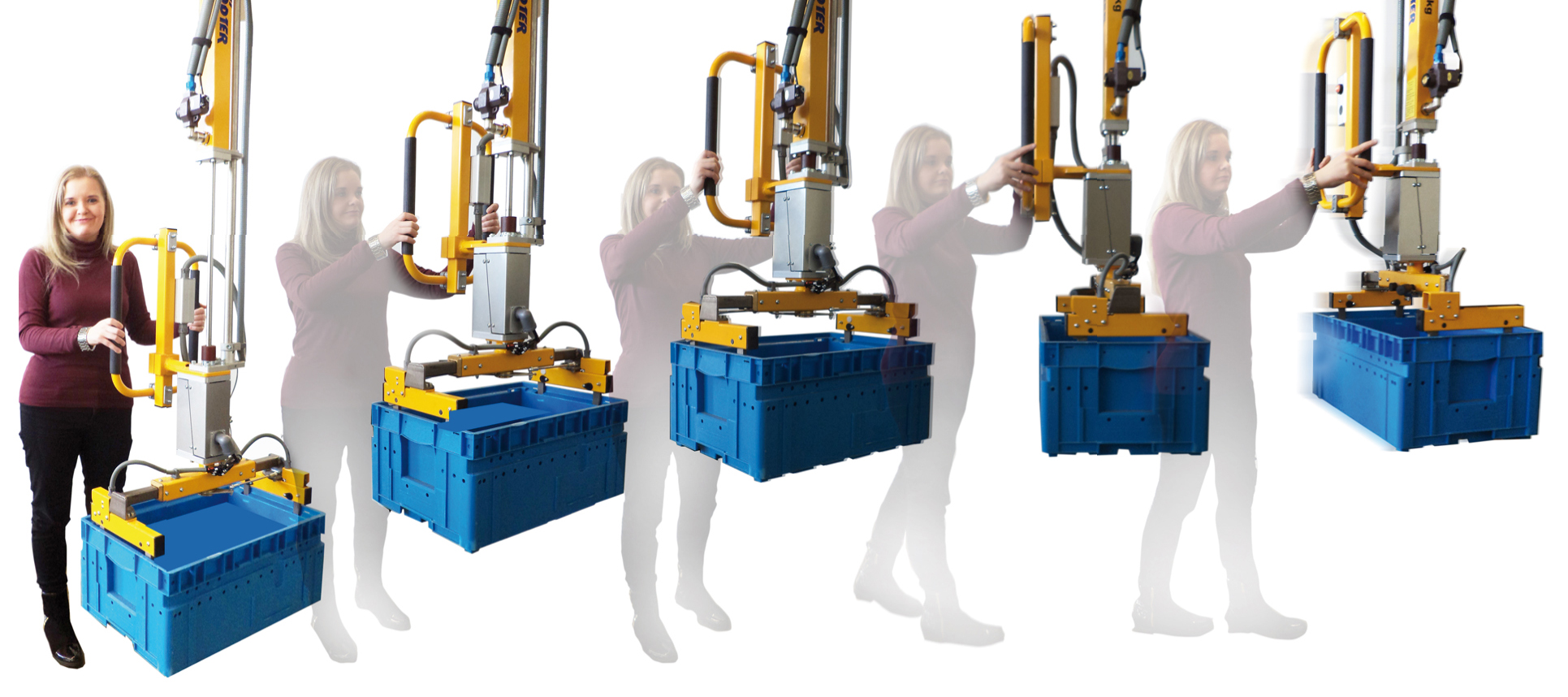

Industrial manipulators and industrial grippersLifting equipment for KLT container handling!

|

|

||||

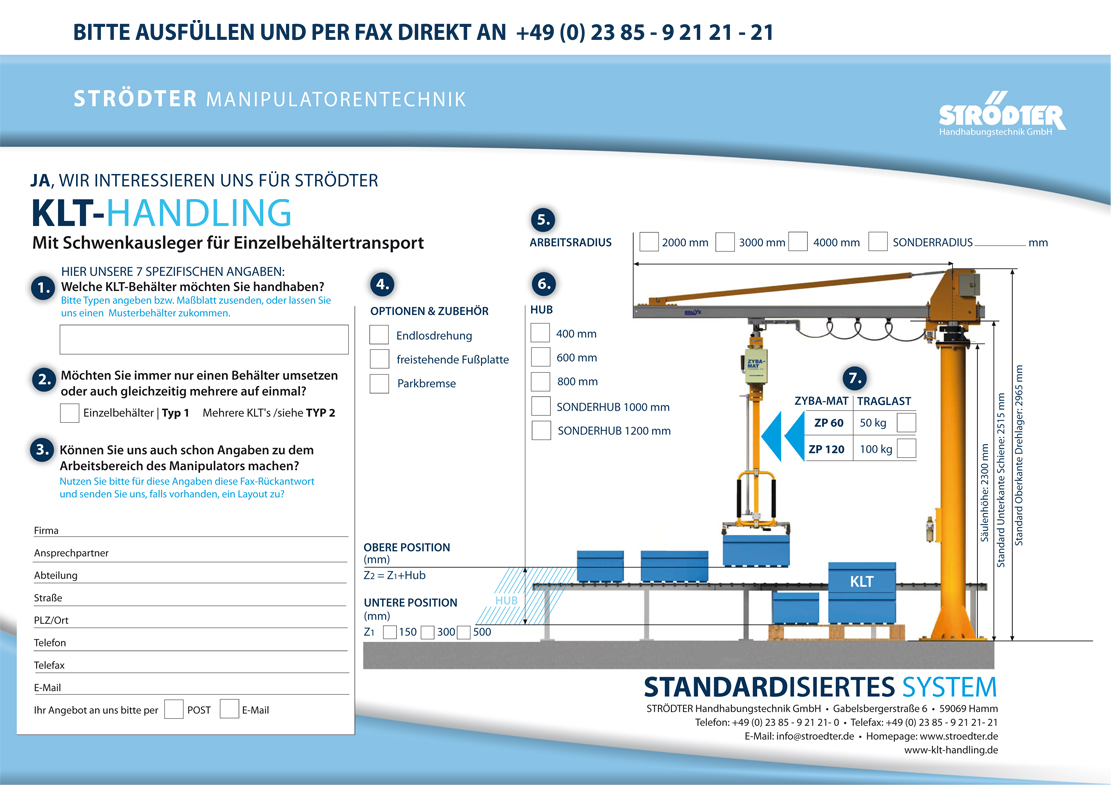

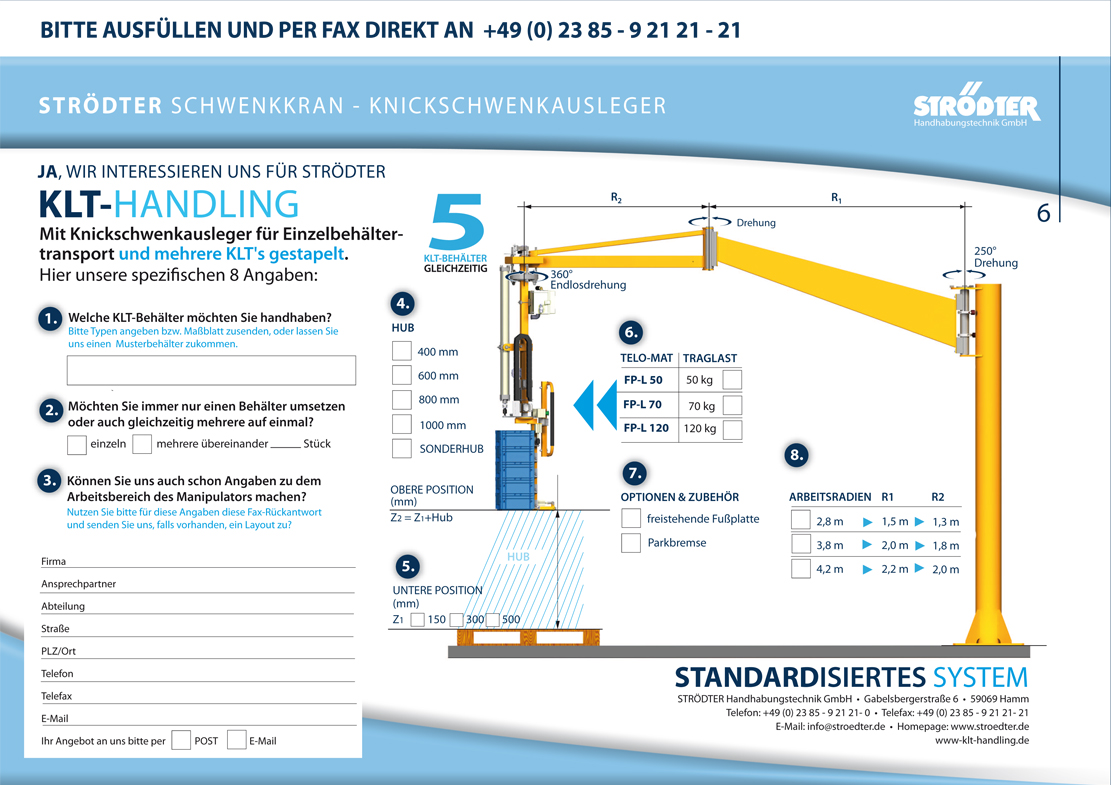

STRÖDTER KLT handlingWherever reusable packaging for small parts or sensitive products needs to be transported, small load carriers (KLT) and large load carriers (GLT) can be used.

For example, in the automotive industry, the standardized KLT‑system from well-known manufacturers has a connecting function in the movement of goods between the supplier industry and the automotive assembly workstations.

From the original development for the automotive industry, other industries have long since used the stackable and easily transportable KLT containers for the transport of production parts Production.  Photo: STRÖDTER Ergomanipulator PICO-MAT with KLT gripper |

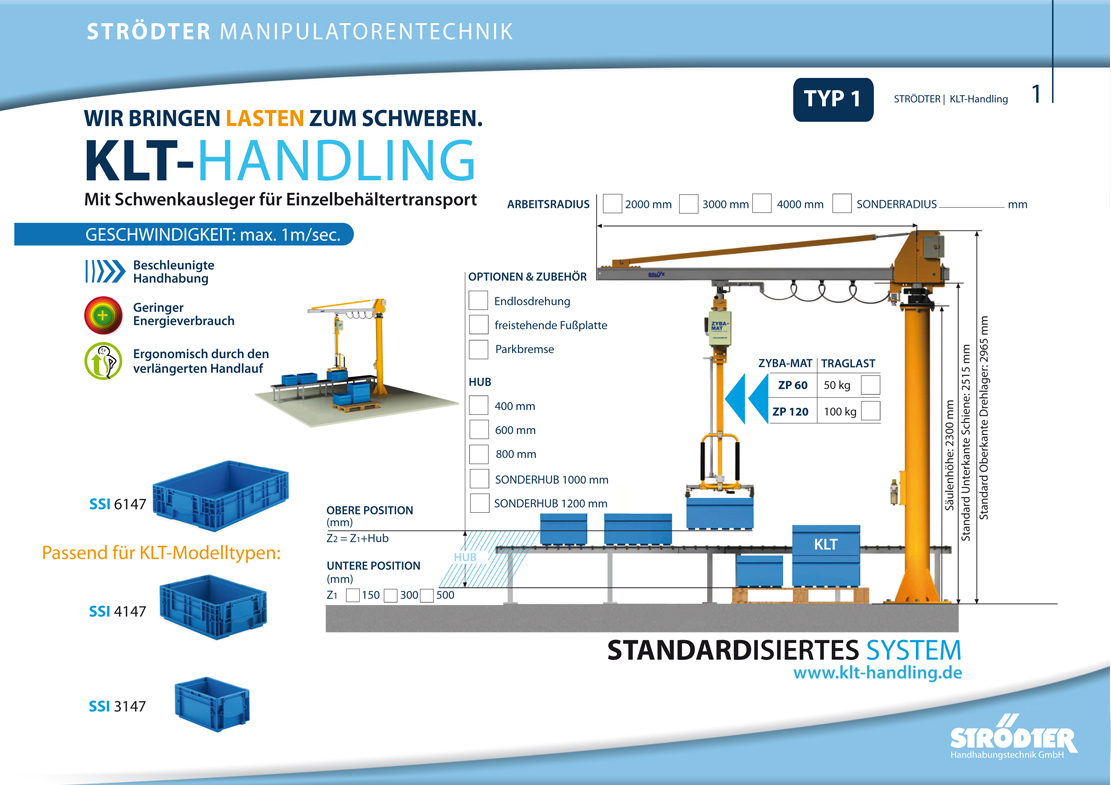

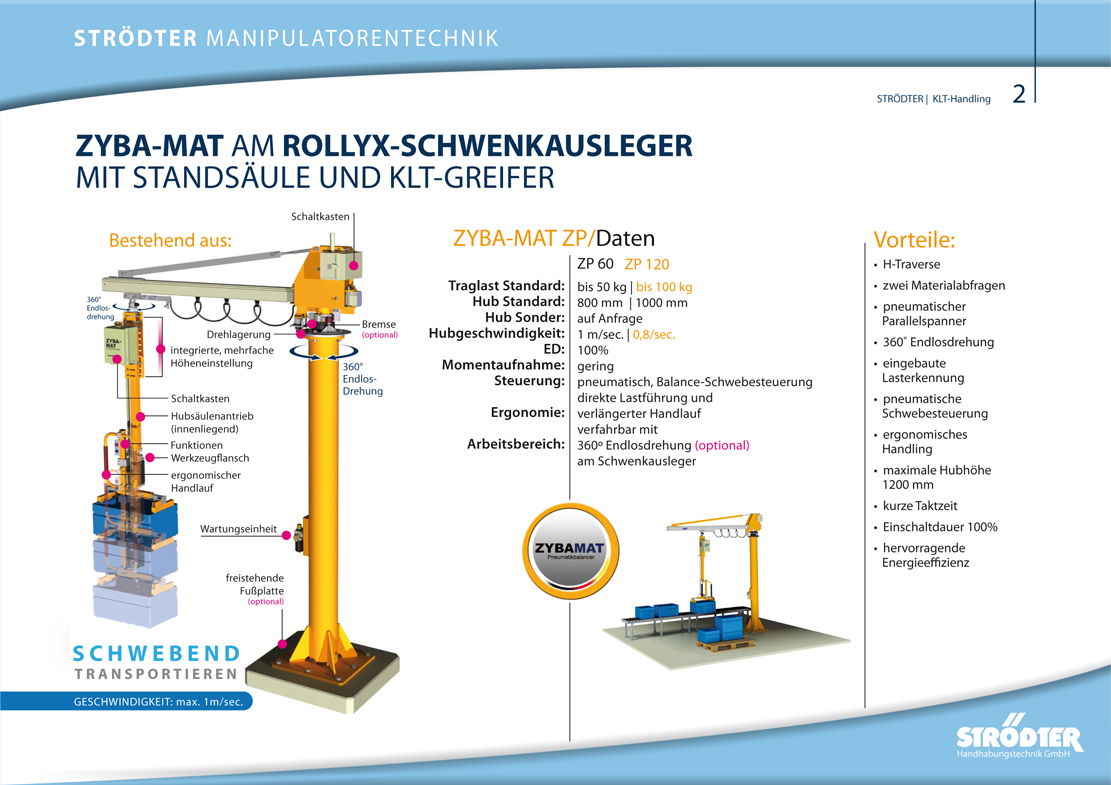

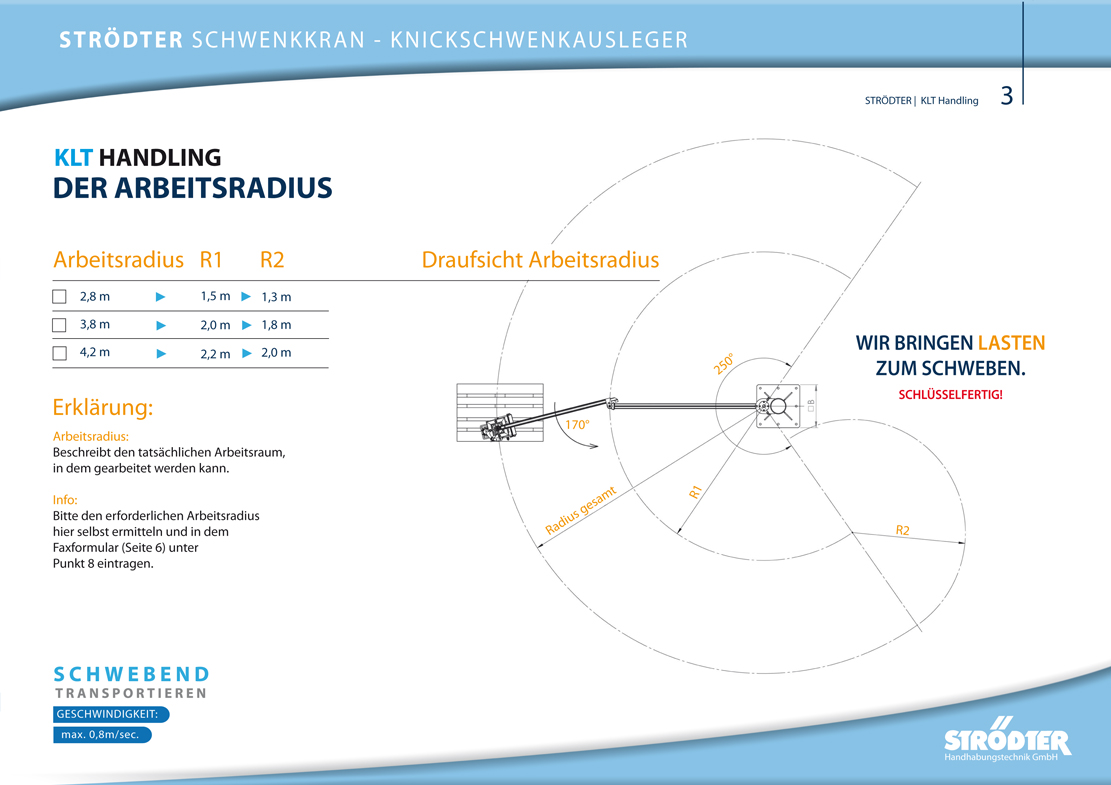

KLT‑Boxes of Euro pallets, the worker must bend down for the deeper stacking layers and stretch upwards for the higher stacking layers. Please click to open the brochure! STRÖDTER Handling‑Manipulators. Special pillar‑articulated arm manipulators for individual workstations or for larger work areas lifting axis manipulators with a smooth‑running rail system

can be used economically as lifting devices or so-called relocators. |

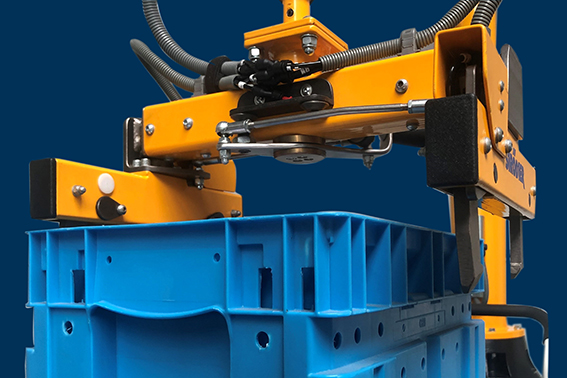

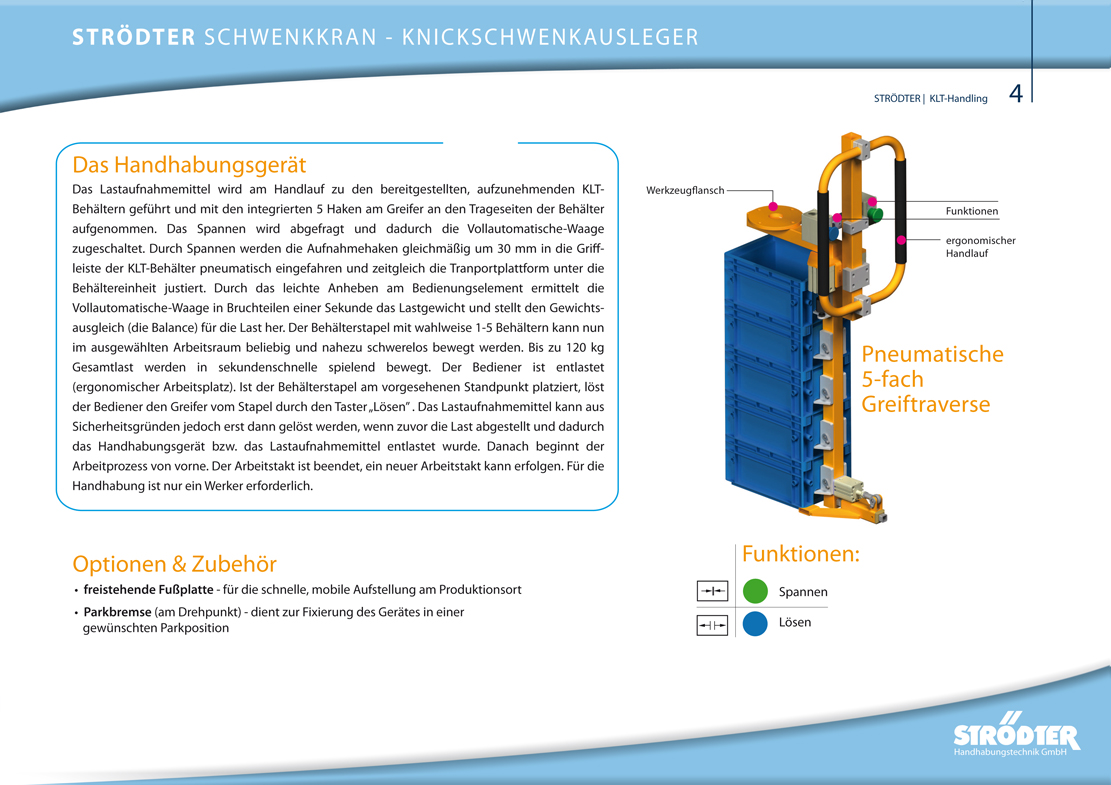

Photo: STRÖDTER lifting aid KLT gripper If it is possible to move several KLT‑boxes (a whole stack) in one operation, then STROEDTER offers special for this >Gripper systems. |

||

STRÖDTER double rope balancer PICO-MAT for lifting KLT  |

STRÖDTER handling manipulator with the HANDLING SYSTEM CELL  |

STRÖDTER PICO-MAT on the POLYGON profile system with ROLLYXPLUS+ rails  |

||

Hovering is better than lifting!

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Efficient warehouse organization with Euro boxes, small load carriers and STRÖDTER handling technology: maximum efficiency and space savings |

|

Handling technology: Maximum efficiency and space saving |

The synergy of EuroBoxes, small load carriers and STRÖDTER handling technology |

Efficient storage thanks to STRÖDTER handling technology |

Tailor-made solutions for your requirements |

Sustainability and cost-effectiveness |

Conclusion: Revolutionize your warehouse organization with STRÖDTER handling technology, Euro boxes and small load carriers. |

| KLT ‑Crates (Small Load Carriers) and Euro‑Containers are used in a variety of industries for the transport and storage of goods and products used. Some of the industries where KLT‑Crates and Euro‑Containers are most commonly used are: |

|

| Automotive Industry: KLT boxes and Euro containers are often used in the automotive industry for transporting auto parts such as engines, transmissions, components and accessories. | Electronics industry: In the electronics industry, they are used by manufacturers for safe storage and for transporting electronic parts, devices and components. |

| Food and beverage industry: In this industry, KLT boxes and Euro containers are used to store and transport food, beverages and packaging materials. | Logistics and transport companies: These companies use KLT boxes and Euro containers to transport and store goods efficiently and safely. |

| Chemical industry:Chemical products and raw materials are often stored and transported in KLT boxes and Euro containers, as these containers make it easier to handle hazardous substances safely. | Retail: Euro containers are often used for display in shops and supermarkets and storage of goods. |

| Mechanical engineering industry: KLT boxes and Euro containers are used in mechanical engineering to transport machines, machine parts and tools. | Pharmaceutical industry: This industry uses KLT‑boxes and Euro& #8209;Containers for transport and storage of medicines and medical products. |

| Textile and clothing industry:Euro containers are often used to transport and store textiles and clothing. | Agricultural technology and food processing: In agricultural technology and food processing, KLT‑ ;Crates and Euro‑containers for the storage and transport of agricultural products and foods used. Agricultural technology manufacturers use them in their manufacturing and production. |

| Download :KLT-Handling-Typ1.pdf oder KLT-Handling-Typ2.pdf | Imprint | Phone: +492385921210 | www.klt-handling.de |

| ©STRÖDTER Handling Technology GmbH 2024 Small Load Carrier (SLC) handling devices and lifting equipment |